Encoders for Lifts and Elevators Industry

Elevators, freight elevators and escalators have become an important part of our daily lives. Elevators help make our lives more comfortable and easier, but their main purpose is to ensure a safe and reliable ride every time. The equipment used in elevators must be safe, robust, precise and reliable. Encoders play a crucial role in meeting these standards, providing precise feedback for smooth, efficient operation.

To ensure the highest level of safety and reliability in your elevator systems, contact us to find out more about our advanced encoder solutions for the elevator industry.

Elevators / lift positioning solution could be applied as follows:

Encoders and solutions for Elevator / Lift speed control

Speed feedback is used to close the loop on the motion of the cabin. The encoder is typically a hollow-shaft encoder mounted on the stub end of the motor shaft (the non-drive end). Because this is a speed application and not a positioning application, an incremental encoder can provide effective performance at a lower cost for elevator speed control.

Encoders and solutions for Elevator traction motor commutation

Gearless traction motor elevators use motor encoders to monitor speed and position, as well as to commutate the motor. Although absolute encoders are often used for commutation, incremental elevator encoders exist targeted specifically for elevator applications. If the incremental encoder is being used to commutate, it must have separate U,V, and W channels on the code disc that enable the drive to control the U, V, and W channels of a brushless motor.

Encoders and solutions for Elevator doors positioning

Encoders also provide feedback to monitor the automatic doors in the elevator car. The doors are operated by a mechanism driven by a small AC or DC motor, typically mounted on top of the car. The encoder monitors the motors to ensure that the doors fully open and close. These encoders need to be hollow-bore designs and compact enough to fit the allotted space. Because the door movement can be slow at the extremes of opening and closing, these feedback devices also need to be high resolution.

Encoders and solutions for Elevator shaft-cabin positioning

Follower-wheel encoders can be used to ensure that the car arrives at the designated location on each floor. Follower-wheel encoders are distance-measuring assemblies that consist of an encoder measuring wheelwith an encoder mounted to the hub. They are typically mounted on either the top or the bottom of the car with the wheel pressed against a structural member of the hoistway. When the car moves, the wheel turns and its motion is monitored by the encoder. The controller converts the output to position or distance of travel.

Encoders and solutions for Elevator overspeed governors

Encoders play a key role in another aspect of elevator operation: preventing the cabin from going over speed. This involves a separate assembly from the motor feedback known as an elevator governor. The governor wire runs over the sheaves then connects to a safety-trip mechanism. The elevator governor system requires encoder feedback to enable the controller to detect when the car speed exceeds threshold and trip the safety mechanism.

Benefits for partners

- Robust encoder construction

- Absolute and Incremental positioning

- Wide range of output Industrial Buses

- Wide range of models

- Customized solutions

Suitable products

Rotary and Linear Encoders

-

AD36 multiturn optical absolute encoder

Product DescriptionThe AD 36 is an optical absolute encoder with a multi-turn gear and optical scanning, size 36 mm. It offers an 8 mm through hollow shaft, which allows resolver-compatible installation. The mechanical concept is based on a shaft assembly mounted in dual ball-bearings with a flexible torque support. The AD36 is suitable for fitting in BLDC servo motors with small frame heights. The BiSS or SSI communication interface enables control circuits to be set up that are completely digital. It is available with resolutions of up to 22 bits single-turn and 12 bits multi-turn.

Multiturn:YesTechnology:OpticalBody Ø, mm:37,5Shaft type:Hollow / HubShaft Ø, mm:8 / 8Temperature (°C):- 15 … 120Speed (rpm):10000Protection Class:IP40Resolution (bit) MT / ST:12 / 12 ... 22Accuracy:+/-35"Interface:BiSS / SSI -

AD58 multiturn optical absolute encoder

Product DescriptionThe AD58 multi-turn absolute encoder is an optical encoder with a multi-turn gear and optical scanning. The mechanical concept is based on a shaft assembly mounted in dual ball-bearings with a flexible torque support. As a result, these encoders are suitable for incorporating in BLDC servo motors and such demanding applications as CNC, precision positioning and high-resolution printing. The encoder is available with resolutions of up to 22 bits single-turn and 12 bits multi-turn.

Multiturn:YesTechnology:OpticalBody Ø, mm:58Shaft type:Solid / HollowShaft Ø, mm:cone 10 / 10 … 12Temperature (°C):- 15 … 120Speed (rpm):10000Protection Class:IP40Resolution (bit) MT / ST:12 / 12 ... 22Accuracy:+/-35"Interface:BiSS / SSI -

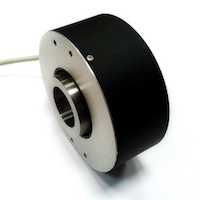

LIR-2100 big hollow shaft optical incremental encoder

Product DescriptionLIR-2100 incremental encoder with big hollow shaft has optical scanning technology. Designed for elevators / lifts application. These encoders feature resolution up to 1024 ppr, hollow shaft 30 mm. Most applied in OTIS 13VTR elevator drives with convertor OVF20 compatible to articles JAA00633ABF003 from Tamagawa (OIH100 TS 5208 N 902)

Technology:OpticalBody Ø, mm:100Shaft type:HollowShaft Ø, mm:30Temperature (°C):-25 … 100Speed (rpm):3000Protection Class:IP64Resolution (ppr):up to 1024Accuracy:up to +/- 150"Output:HTL -

LIR-276 big hollow shaft optical incremental encoder

Product DescriptionLIR-276 incremental encoder with big hollow shaft has optical scanning technology. Belongs to Industrial Basic encoders characterized by being particularly flexible and has wide range of applications. These encoders feature good accuracy and high resolution up to 500 000 ppr, hollow shaft 24 mm, particularly well suited to use in machine tools, CNC axes, packaging machines, motors / drives, injection moulding machines and sawing machines, lifts and printing machines.

Technology:OpticalBody Ø, mm:76Shaft type:HollowShaft Ø, mm:24Temperature (°C):-40 … 100Speed (rpm):3000Protection Class:IP64Resolution (ppr):up to 500 000Accuracy:up to +/-15"Output:TTL / HTL / 1Vpp

-

MSC500 incremental magnetic linear encoder

Product DescriptionCompact sensor, incremental, digital interface, resolution 1 μm.

The MSC500 magnetic sensor has a large, multi-color status LED that makes commissioning and function monitoring easier for users. The correct distance between the gage and the sensor can be visually monitored.

With the plug connection directly on the sensor head, the MSC500 is also suitable for use in very confined spaces. As a result installation is fast and simple, which naturally means lower costs. In addition, the MSC500 sensor includes all digital square wave signals. This enables evaluation of the A/B signals, the inverted signals and the periodic index signals with the same sensor. Main features: Max. resolution 1 μm, Max. 200000 pulses/revolution in combination with MR500 or MBR500 (160 poles), Repeat accuracy ±0.005 mm, Status LED with integrated distance monitoring, Works with magnetic tape MB500/1, MR500, MBR500, Reading distance ≤2 mm, Sensor connection can be plugged with KV1C cable extension, Output circuit PP, TTL, LD (depending on the operating voltage), possible with fixed reference marks R or flexible reference marks FR.Technology:MagneticMeasuring Length, m:≤ 100Temperature (°C):-40 … 85Speed (m/s):≤ 25Protection Class:IP67Pitch, mm:5Resolution (μm):1 … 100Accuracy (μm/m):± 25Output:TTL / Push pullStatus LED:YES -

MSK1000 incremental magnetic linear encoder

Product DescriptionIncremental, digital interface, resolution up to 0.2 μm

Encoder simple to install with help of status LED, wide installation tolerances, special tools and adhesive-backed magnetic scale. It’s operate non-contact and has no friction so makes possible to reduce hysteresis. High protection up to IP67 and resistance to shock, vibration, some chemical environments allows to use Magnetic Encoder MSK1000 in Medical technology (e.g.: Tomographs, operating tables), Linear drive technology, Torque motors, Stop systems (e.g. wood working), Sawing technology (wood, metal, stone working), Elevator technology, Warehouse and conveyor technology, Presses, Special engineering. Main features; Max. resolution 0.2 μm, Repeat accuracy ±1 μm, Status LED display, Reading distance ≤0.4 mm, Robust metal housing.

Technology:MagneticMeasuring Length, m:4; 100Temperature (°C):-10 … 70Speed (m/s):≤ 16Protection Class:IP67Pitch, mm:1Resolution (μm):0,2 … 5Accuracy (μm/m):± 10Output:Line DriverStatus LED:YES -

MSK200/1 incremental magnetic linear encoder

Product DescriptionIncremental, digital interface, resolution up to 1 μm

Encoder simple to install with help of status LED, wide installation tolerances, special tools and adhesive-backed magnetic scale. It’s operate non-contact and has no friction so makes possible to reduce hysteresis. High protection up to IP67 and resistance to shock, vibration, some chemical environments allows to use Magnetic Encoder MSC200/1 in Medical technology (e.g.: Tomographs, operating tables), Linear drive technology, Torque motors, Stop systems (e.g. wood working), Sawing technology (wood, metal, stone working), Elevator technology, Warehouse and conveyor technology, Presses, Special engineering. Main features: Max. resolution 1 μm, Repeat accuracy ±0.01 mm, Works with magnetic tape MB200/1, Reading distance ≤1 mm, Possible with fixed reference mark R or flexible stick on reference mark FR.

Technology:MagneticMeasuring Length, m:≤ 100Temperature (°C):-10 … 70Speed (m/s):≤ 25Protection Class:IP67Pitch, mm:2Resolution (μm):1 … 10Accuracy (μm/m):± 25Output:Line DriverStatus LED:NO -

MSK5000 incremental magnetic linear encoder

Product DescriptionIncremental, digital interface, resolution up to 1 μm

Encoder simple to install with help of status LED, wide installation tolerances, special tools and adhesive-backed magnetic scale. It’s operate non-contact and has no friction so makes possible to reduce hysteresis. High protection up to IP67 and resistance to shock, vibration, some chemical environments allows to use Magnetic Encoder MSK5000 in Medical technology (e.g.: Tomographs, operating tables), Linear drive technology, Torque motors, Stop systems (e.g. wood working), Sawing technology (wood, metal, stone working), Elevator technology, Warehouse and conveyor technology, Presses, Special engineering. Main features: Max. resolution 1 μm, Repeat accuracy ±0.01 mm, Status LED display, Works with magnetic tape MB500/1, Reading distance ≤2 mm.

Technology:MagneticMeasuring Length, m:≤ 100Temperature (°C):-10 … 70Speed (m/s):≤ 25Protection Class:IP67Pitch, mm:5Resolution (μm):1 … 10Accuracy (μm/m):± 25Output:TTL / Push pullStatus LED:YES

-

AC58 multiturn optical absolute encoder

Product DescriptionThe AC58 series combines a series of absolute rotary encoders with optical scanning for numerous fields of application. The 58 mm encoders are available as solid-shaft or hollow-shaft models and meet the requirements for nearly every demanding industrial application and use involving motor feedback. As single-turn and multi-turn versions, these encoders achieve a resolution of up to 34 bits (22 bits single-turn, 12 bits multi-turn, depending upon interface). Apart from connections by SSI/ BiSS, many other interfaces such as EtherCAT, Profibus, CANopen, CANlayer2, DeviceNet, Interbus and SUCOnet are available.

Multiturn:YesTechnology:OpticalBody Ø, mm:58Shaft type:Solid / HollowShaft Ø, mm:6 … 12/ 9,52 … 14Temperature (°C):- 40 … 100Speed (rpm):10000Protection Class:IP50 / IP64 / IP67Resolution (bit) MT / ST:4 … 12 / 10 ... 22Accuracy:+/-35"Interface:BiSS / SSI / CANopen / CANLayer2 / Profibus DeviceNET / Inerbus / Parrallel / SUCOnet / EtherCAT / SSI programmable -

HS35R Heavy Duty Hollow shaft Encoder

Product DescriptionThe flagship of the Dynapar product line, the HS35R series is the ruggedized version of the original vector-duty hollow-shaft encoder. With 400g shock rating, IP67 sealing, and wide -40ºC to 100ºC temperature range, the HS35R raises the bar on vector-duty encoder performance providing increased reliability and maximize equipment uptime in mill and heavy duty plant environments. Application: Drawworks drums, mud pumps, catwalks, hoists, winches & motors, Motor and drive speed feedback, Converting Machinery, Material Handling, Packaging Equipment, Pickling Equipment, Processing Equipment, Elevators, PLC’s and electronic counters musement rides.

Body Ø, mm:96,52Shaft type:HollowShaft Ø, mm:6…28Temperature (°C):-40 ... +100Speed (rpm):6000Protection Class:IP67Resolution (bit) MT / ST:up to 5000Output:Open Collector / Push pull / RS422Housing Option:AluminiumConnection:Cable / Connector -

RI58 optical incremental encoder

Product DescriptionThe universally applicable industrial incremental encoders in the RI58 family are characterised by being particularly flexible. There are a number of different versions offering a range of flanges and connections. These encoders are suitable for high shock loads and feature high signal accuracy and up to 40,000 steps with 10,000 marks and are particularly well suited to use in machine tools, CNC axes, packaging machines, motors / drives, injection moulding machines and sawing machines.

Technology:OpticalBody Ø, mm:58Shaft type:Solid / HollowShaft Ø, mm:6 … 12 / 6 … 15Temperature (°C):-25 … 100Speed (rpm):10000Protection Class:IP40 / IP50 / IP64 / IP67Resolution (ppr):up to 10 000Accuracy:+/-75"Output:Push pull / RS422